Fixtures & Prototypes

Fixtures and Test Jigs

|

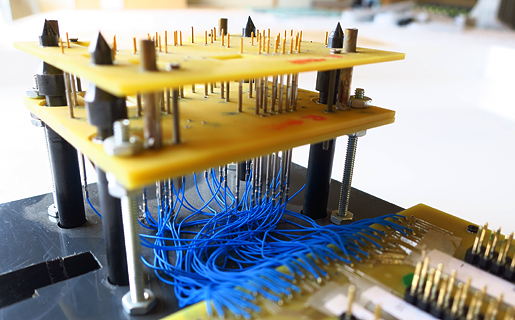

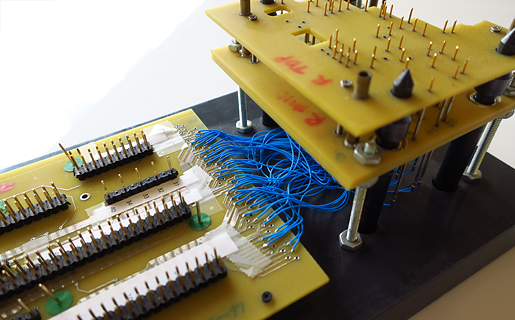

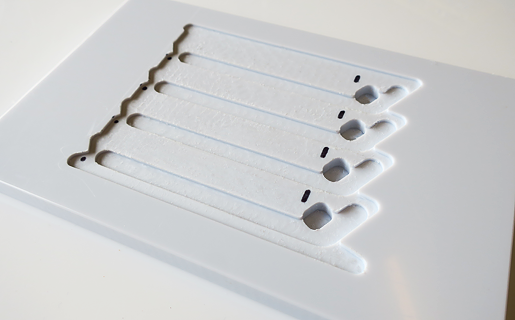

Test fixture with pogo pins. Designed 2013.

|

|

|

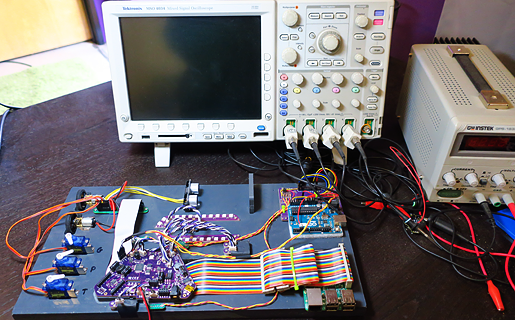

Testing FixturesI've created a few complex testing fixtures over the years. This is one example that automatically tests all functions of a robot mainboard. The various motors, servos, and sensors of the robot are positioned on the test fixture, connected to the main board under test with a pair of ribbon cables.

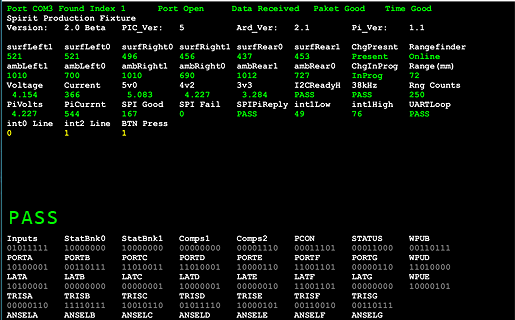

The fixture uses an Arduino board together with a custom processing board we designed (upper right corner) to stimulate sensors at a specific timing. An oscilloscope connects to the fixture where pass/fail parameters are stored. Data is sent to a host PC from the board under test and the Arduino controller board. Data is streamed to a PC/Windows interface designed in Processing where all measurements and parameters are displayed to a test operator. The test program displays a clear PASS/FAIL, and any parameters outside of defined limits show up in red for the operator. The bottom section shows the binary values of several important microcontroller registers on the board under test, where failures can be easily analyzed. A system like this can also be used to store test results to a database, load unique serial numbers, encryption keys, and the like onto the board under test. |

Testing fixture with oscilloscope and PC integration. Designed 2017.

PC interface for the above testing fixture. Designed 2017.

|

|

Test fixture with pogo pins. Designed 2013.

|

R&D and Pinboard FixturesThese fixtures use pogo pins to connect to test points on a board, then electrically break out those test points to pin headers. These headers can be pinned into with an oscilloscope or other circuitry. This strategy speeds design by allowing easy debugging of code on an actual finished board without requiring hair wires or solder connections to the board.

These fixtures can also be standardized for automated electric testing on production lines. |

Processing FixturesVarious work holding fixtures can be used in production processes. Customized for a given application they can be fabricated out of various materials.

Simple fixtures with tight tolerances can be machined on the CNC or they can be 3D printed for more complex designs. |

Alignment fixture for soldering process. 2016.

|