Plastics Fabrication

Working with Plastics

|

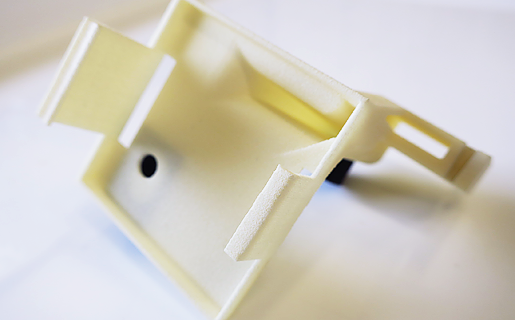

End cap for inspection tank. Designed 2018.

|

Simple Fixtures to Full Product Development |

|

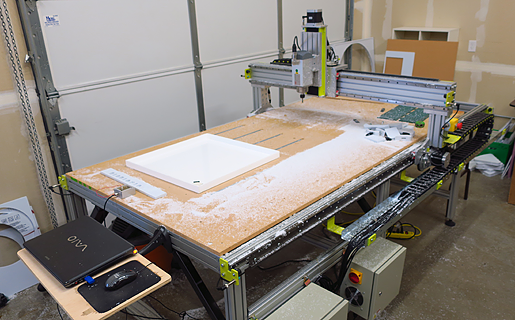

I often work with plastics. I began using plastics for electronics enclosures and robot parts. I love working with the material and now run an in house 4'x8' CNC router to make a wide range of parts for different applications.

|

|

|

CNC Plastics MachiningI can fabricate just about anything from plastic. Most parts can be made in house. If more complex parts are needed I have relationships with several production shops locally that have more specific capabilities for more specialized parts.

I can work with just about any kind of plastic as well as wood and soft metals like aluminum. Our partners can handle steel and parts made from more exotic materials with HAAS and Tormach mills. I also have access to water jet, plasma, and laser cutting services through local partners. |

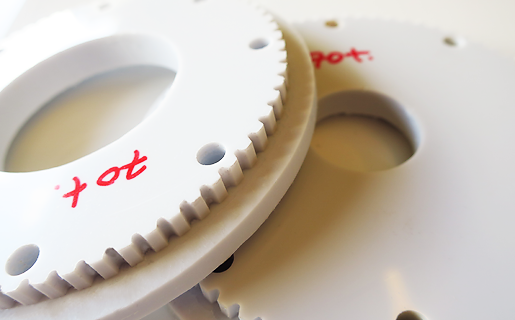

Gear system for belt drive. Designed & Machined 2017.

|

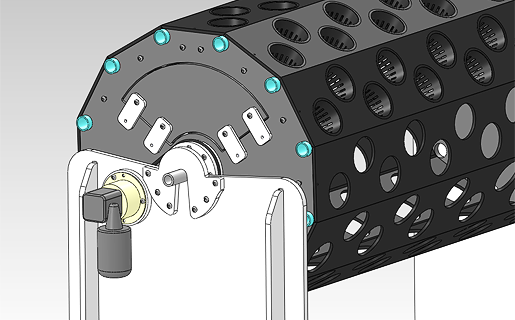

Product DesignI've designed and fabricated complex designs with many parts and mechanical moving parts.

This is a complete design of a growing system for agriculture I designed in 2018. It is made of over sixty plastic parts and includes ball bearings, motor drive, plumbing, and electronics for monitoring water quality. We fabricated all the parts in house and plastic welded the parts together for a functional prototype. |

Growing system for agriculture. Designed & Fabricated 2018.

|

|

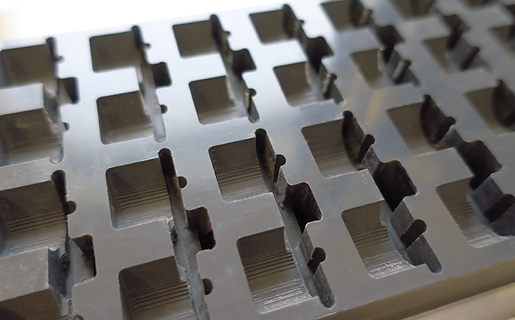

Production process fixture, machined from PVC. 2017.

|

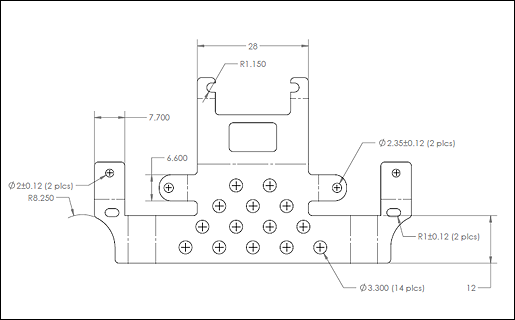

FixturesI often work with processing fixtures, holding racks, construction jigs and other odd shaped parts designed for a specific purpose.

I am able to design these fixtures from scratch based on the specific application where they will be used. We can integrate electronics into fixtures as well if testing or measuring is required by the application. |

Rapid Prototypes and 3D PrintingFor more complex parts, there are various rapid prototyping and 3D printing technologies we can use to produce the perfect part.

Though I don't have 3D printing ability in house, I do have working relationships with several individuals and companies that run the full range of 3D printing technologies. They have reasonable costs and fast turnaround time. |

High resolution 3D printed rapid prototype. Designed & produced 2009.

|

|

|

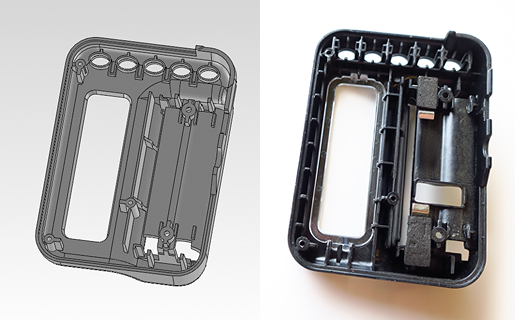

Injection molded enclosure with complex parting lines. Designed 2013.

|