Electronics Design

Embedded Hardware

|

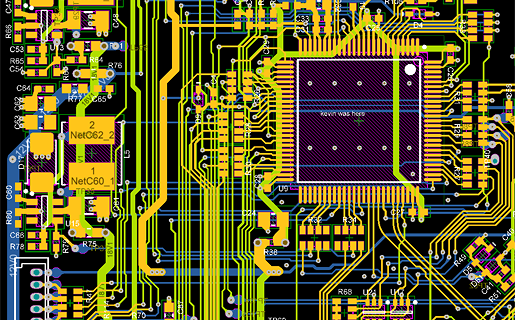

Six layer main board for photographic lighting. Designed 2012.

|

Design Assistance and Product Development |

|

I look forward to assisting your team with product development. I'm a team player and ready to take on existing projects or consult in planning new ones. If it needs a circuit board, I can make it happen.

|

|

|

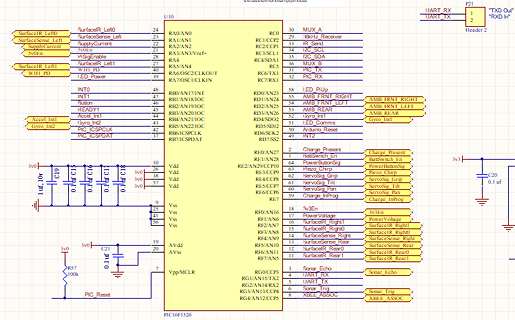

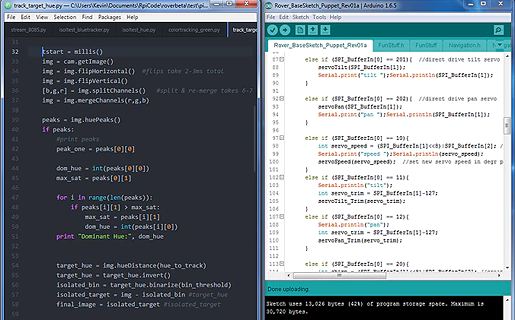

Schematic DesignWorking from a new concept or existing design, I take pride in clean, clear schematic work. Well documented with well maintained part libraries. I leverage open source designs and reference designs where possible to minimize design time.

This is the point we select appropriate components. We want to use parts that are readily available with alternate parts if needed. We select the lowest cost components suitable for the application. |

PIC16 based robotics controller. Designed 2016.

|

|

High speed IGBT power system controller. Designed 2011.

|

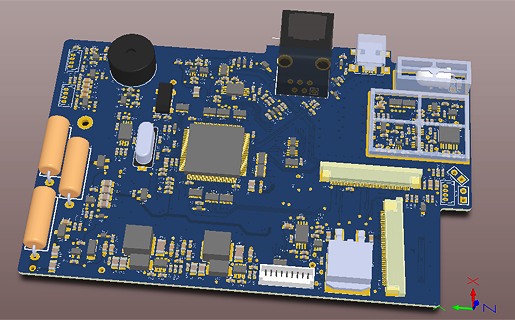

Board LayoutI really enjoy the process of laying out boards. I've worked with very simple boards ranging up to six layers, including mixed signal and high speed boards. Hand routing the boards manually results in a clean product with maximum component density. Boards can be any shape and from any material as appropriate for the application.

Once designed I am able to order any quantity needed ranging from proof of concept prototypes to production. I can create any required supporting documentation for ordering solder stencils and programming pick and place machines. |

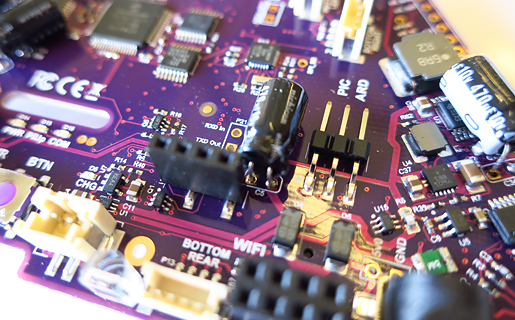

Production PrototypesI find hand soldering prototypes is usually faster than programming up the pick n' place machine. We can go either way depending on quantity. I use various soldering methods to build high quality prototypes and very short runs. I take great pride in clean work.

|

Robot main board. Hand soldered. Prototype 2016.

|

|

Employee of the Year. 2014~Present.

|

Short Run ProductionThis is our trusty Quad 4c pick n' place machine. It's 30 years old, runs on DOS 6.22, and still runs like a champ. It does get grumpy from time to time, but generally we can handle a wide range of components. From 0402 to large high pin count components, it'll handle the job. It takes a while to program a new board as the process is mostly manual, but it's a perfect tool for short to mid runs of simple boards.

If your board is more complex, I have long standing relationships with several full time contract manufacturers here in the USA. I'm happy to do the legwork with them to get your boards quoted, run, and assembled. |

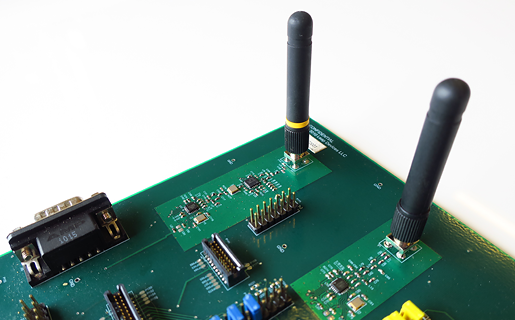

Radio Systems & Internet of ThingsIf your device involves Internet of Things (IoT), the MQTT protocol, or needs to interact with WiFi, Bluetooth, Mesh Networking, or simple data transmission, I'm comfortable working with various radio modules as well as radios designed from discrete parts. I can assist with antenna design and integration.

I've taken twelve production devices through the FCC process and haven't failed a test so far. I'm available to assist with understanding FCC Part 15 as well as IC or other certifications. I have a longstanding relationship with two test labs here in the USA, as well as connections to test labs in Asia. |

Radio comms device, 900MHz and 2.4GHz, ready for FCC Part 15 certification. 2011.

|

|

|

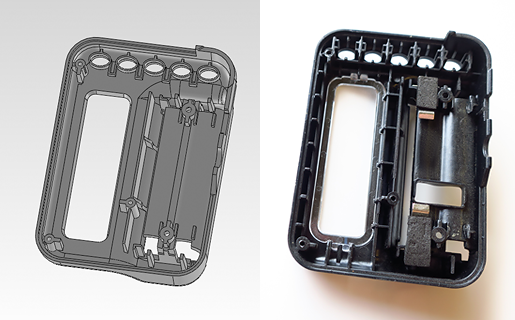

Injection molded enclosure with complex parting lines. Designed 2013.

|

|

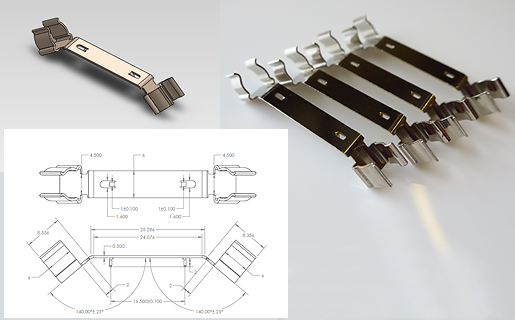

Custom stamped metal mounting bracket. Designed 2015.

|

Stamped Metal PartsI can design all kinds of stamped metal parts, taking into consideration how they will be machined. I have a relationship with a metals factory in China that can stamp parts from most metals as well as application of nickel plating, anodizing or other finishes. Custom wire bending, springs, and antennas can be made in a similar way.

This is a great way to save cost on custom parts like battery contacts, frames, and electronic shielding on medium to large production runs. Metal stamping tooling is fairly low cost. |